It is impossible to understand the science of shoes until one understands what science is.”

-Plato, The Theaetetus

Despite the likely need for pedorthic services in ancient Athens, I doubt that Plato was a shoemaker. However, Plato’s quote gets to the heart of learning in the real world: it is vital to understand the fundamentals of a subject before applying it to practical situations. Too often, armed with a little knowledge and a lot of hope, we can find ourselves wishing for solutions that never materialize because we have not grasped certain core principles. Custom shoes are one such area where a clear understanding of the science can alleviate a lot of heartache.

There are a number of reasons why custom shoes can be very tricky to fit. The typical patient for custom shoes presents with severe pathology, which can range from excessive edema, Charcot breakdown, and advanced neuropathy, to obesity. Other orthopedic conditions can include some form of contracture, surgical fixation, post-polio syndrome, or congenitally mismatched feet. Regardless of etiology, the desire is for a shoe that enables full function-pain free-while also being cosmetically pleasing.

To complicate matters, patients may not accept their foot condition. As an example, it is important to educate diabetic patients who may not understand the vital importance of well-fitting and protective shoes. Patients frequently complain about the “ugly look” of these shoes, unaware of the benefits. Compounding the issue, some patients may have a secondary condition such as depression or a sedentary lifestyle that results in low levels of ambulation. This starts a cycle in which inactive patients walk less, gain more weight, and so become less active. Pedorthists live to provide the right shoes to keep people moving.

Custom shoes are only for that segment of the population that cannot wear other styles of extra-depth or orthopedic shoes. The primary requirement of good custom shoes is fit. For the vascularly impaired or neuropathic patient, the fit-and the resulting protection it offers-must be superb. The fit may be the difference between a patient remaining active, and therefore healthier, or losing a limb. Studies show that any digit or partial-foot amputation is a reasonably good predictor of further limb loss and higher patient morbidity.

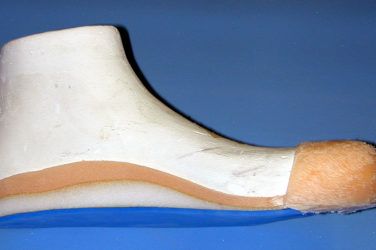

Without question, the cast is the single most important aspect of the custom-shoe process. Time and again, analyses of custom-shoe success rates shows that a quality cast is the number one factor in determining the fit and acceptance of a shoe. A good-quality shoe cast is one that represents the entire semi-weight-bearing functioning foot.

An accurate cast will (1) capture the position-of-function; (2) account for any edema; and (3) include any other traditional orthotic devices that will be worn inside the shoe. The position-of-function is important especially when accommodating a fixed deformity. If foot is held in equinus or plantarflexion, the cast should be taken with the patient standing.

Casting for Custom Shoes

Here are some casting guidelines to help ensure a good and properly fitting shoe:

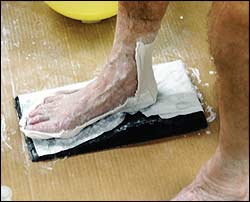

1. Seat the patient in a regular chair with his or her feet flat on the ground and the lower leg perpendicular (at 90 degrees) to the floor. Use a casting board with a 0.5-in.+/- pitch. Apply a separating agent, such as liquid soap or Vaseline, to the skin if necessary.

2. For patients with severe rigid deformities, cast them in the position of function; i.e., standing. Make special note of the rigid deformity on the prescription form, and if possible indicate vertical plumb-lines on the lower leg. Typically, all casts will be corrected to balance the lower leg to 90 degrees unless otherwise noted.

3. Place a soft foam cushion under the feet. The goal is to create a semi-weight-bearing cast that captures (a) the full width of the metatarsals; (b) the full length of the extended foot and toes; and (c) the contours of the foot at the heel and arch. If the patient is going to wear a brace, AFO, compression stocking, or bandage, cast him or her with it on.

4. When using plaster, the bivalve or clamshell technique is the preferred method. It helps to ensure that there is little distortion of the foot, and it is easy to mark any areas of concern inside the cast. If using the plaster “wrap” technique, be especially aware of maintaining the full width of the metatarsals.

5. When pulling on or using the casting stockings, make sure that the toes remain fully extended; otherwise, the shoe may come back too short.

6. Plaster and fiberglass wraps must not be wound overly tight, and the toes and mets should not be restricted. Bring the cast to at least 1 in. above the final height the shoe will be.

7. Explain to patients what you are trying to achieve so that they don’t shift or move during the casting, and that they maintain the 90-degree angle. Write the patient’s name on the cast before you remove it.

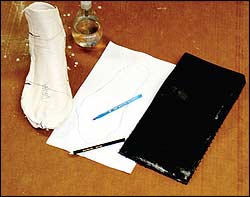

8. Make pencil marks across the cut-line of the cast to indicate alignment before removing or opening with a cast saw. This is very helpful to the lab when they pour the positive mold. Peel the cast away gently so as not to distort the shape.

After removing, check the final cast and ensure that (a) it stands on its own; (b) the lower leg is vertical (unless there is a rigid deformity); and (c) areas of concern are marked. As a simple test, the final cast should stand erect, unsupported. If it lists or wobbles like a drunken sailor, this usually indicates a problem.

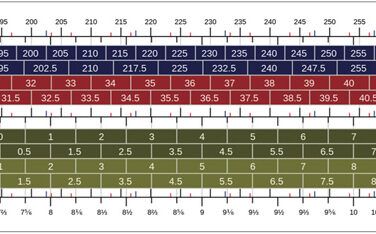

After the casting is complete, take a full weight-bearing tracing of the patient’s feet. If the patient has an existing comfortable pair of custom shoes, trace the insoles.

A good cast and clear prescription will go a long way toward well-fitting and comfortable custom shoes.

These errors should be avoided. Any one of them can spoil a good outcome.

- The number-one offender is poor toe definition! This is especially true when fiberglass is used. It is essential to crimp the distal end of the cast around the toes without pushing the toes back. In addition, you must provide a full weight-bearing tracing of the patient’s feet, as this will be the only verification that the lab has before shaping the last.

- If the wrap (plaster or fiberglass) is too tight, it will compress and artificially narrow the foot. Conversely, casts that are too loose lack anatomical definition.

- Occasionally, a patient may have to be cast in a wheelchair or lying supine. Casts that are taken non-weight-bearing should be clearly noted as such.

- If an AFO is not available at the time of casting, it is best to send it on to the lab so they can incorporate it into the final last.

|

|

| 1. Preparation of materials | 2. Apply to plantar and posterior |

|

|

| 3. Take a full weight-bearing tracing |

4. Check quality of cast and complete the Rx form |

Hard-won experience has demonstrated to me that the best cast technique is the plaster clam shell. It captures the true shape of the foot and toes without restricting tissue. If time and cleanliness are an issue, using a casting sock is a close second. Plaster wraps can work if the toes are clearly defined and the bandage is not too tight. Without question, I consider fiberglass to be the worst! At the risk of sounding redundant, tracings are a great safety net and essential for checking the cast elongation.

Over 2,400 years ago, Plato developed the concept of the Ideal Form. For example the “ideal chair” is something that one could imagine, with a form and function distinct from, say, that of a table. All chairs in the real world are then compared or referenced to this “ideal.” In the case of fitting custom shoes, it is vital to ensure that the cast is as close to the “ideal” as possible. That will make your patient, and Plato, quite happy.

Séamus Kennedy, BEng (Mech), CPed, FAAOP(A) is president and co-owner of Hersco Ortho Labs, New York, New York. He can be contacted at seamus@hersco.com or by visiting hersco.com.