Metrology is the science of measurement. It develops units and references that allow accurate comparison of instrument observations. Dependable measurement systems rely on standards and fixed points of reference. However, every shoe fitter knows this is clearly not the case for footwear. One of the more intriguing aspects of pedorthics is reconciling the science of shoe sizing with the art of proper fit.

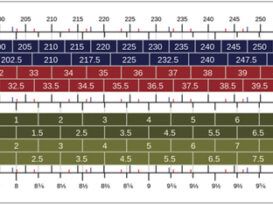

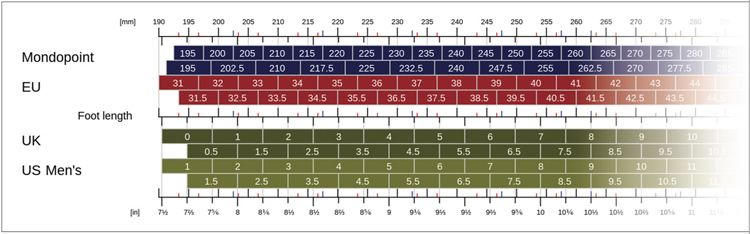

Part of the problem is the variety in anatomy and function of the human foot. It is estimated over half of the population have different sized feet either in length or width. Very often these differences are subtle and can be ignored, but sometimes they affect shoe fit and comfort. For example, a person with bunions may have one larger than the other, or a low arched foot might be unilateral. Secondly, there are many different sizing standards used throughout the world, Fig. 1. Attempts to develop a universal metric such as ISO’s Mondopoint have not been widely adopted by manufacturers. Further compounding the issue, shoes are made all over the world for disparate markets. Many people easily own a dozen or more pairs made across the globe in China, India, Vietnam, Indonesia, Brazil and other countries.

Fully aware of these complications retailers and experienced pedorthists must have an intimate knowledge of their inventory. The absence of standards has plagued on-line shoppers so much that even Millennials prefer to purchase shoes in a store! Acknowledging the sizing discrepancies some websites offer guidance such as “fits true to size”, or “runs big (recommend a full size down)”.

Historical Standards

Shoe making developed as a craft long before the requirements of mass production could impose strict standards and scientific rigor. Originally, measurements were comparative and references used since Roman times included an inch as the width of a man’s thumb at the base of the nail, and a foot conveniently was the length of a man’s foot. According to lore, in the 12th century King Henry I of England brought order to the realm by literally putting his foot down and declaring that to be the standard 12 inches. Not to be outdone, two hundred years later, Edward II decreed “3 grains of barley, from the middle of the stalk and dried, laid end-to-end” would henceforth equal one inch. By convenience some English shoemakers adopted this barleycorn metric and used it when sizing feet. At times, shoe sizes have been set in 1/4” or 1/2” steps, but still today 1/3” remains a widely accepted standard increment in shoe size and last design.

Measuring Feet

It is important to remember we do not actually measure shoe size, as every shoe last is constructed differently. The length of the last depends on details such as the height of the heel and the toe box shape. Foot size is measured, which in turn provides an indication of shoe size. Always measure both feet heel-to-toe with the person standing, noting the longest toe is sometimes the 2nd, and occasionally the third. Fit the shoe to the longest foot.

The Ritz stick is a popular and widely used tool to gauge shoe size. Manufactured in the USA it is a simple wooden slide rule embossed with Mens’s and Women’s shoe sizes. It also allows measurement of width, and includes a width conversion chart on the reverse side. Most professionals prefer the Brannock Device ® which Charles Brannock developed while attending university and patented in 1927 (www.brannock.com). He first used the device with great success in his father’s shoe store in downtown Syracuse, New York. The formula used by the Brannock device assumes the length of the foot to be 2/3 inch (1.7 cm) less than the length of the last (Figure 2).

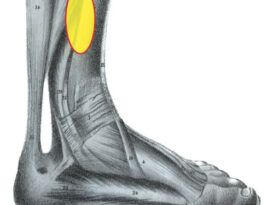

The advantage of the Brannock is it records three key measurements: Heel to longest toe, width at the ball, and the heel-to-ball length. Each of these are fundamental to proper fit. The 1st Metatarsal Phalangeal Joint should sit at the widest part of the shoe and the heel-to-ball measurement should match the flex line of the shoe, otherwise it will be uncomfortable to wear even though its overall length may be correct. Likewise, the heel to 5th met head, or outer-ball, should align with the shoe’s break point.

Beyond linear measurements circumference is also important. The girth at the ball, the waist and the instep of the last determine the volume of the shoe and are key components of the design. In fact, there are over a dozen distinct criteria involved in ensuring a properly fitted shoe, including heel width and malleolar height. Finally, remember the foot can change size over the course of a day, and typically lengthens over the years, so it is very important to remeasure periodically.

Adding to the confusion there is no agreement on how much space should be available at the end of a well-fitting shoe. The Brannock allows generously for 2 barleycorns (0.66”) difference between the foot and the length of last. Some European countries rely on the Paris point unit, which is 6.66mm, or 0.26”. European lasts are sized 2 to 2.5 Paris points longer than the foot, approximately 13 – 16mm of room, or at least 1/2”.

The formula for calculating European shoe sizes is: (Foot length in cm x 1.5) + (2 or 2.5)

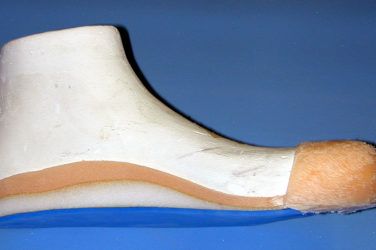

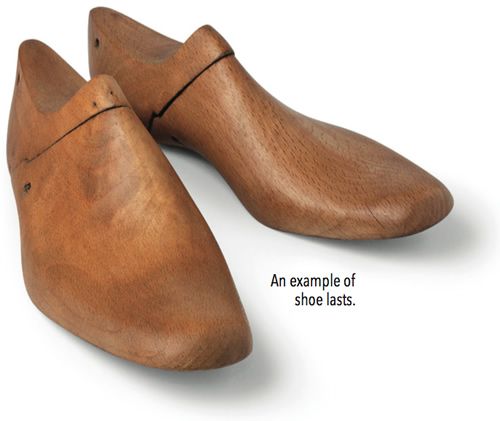

Shoe Lasts

A shoe last is the solid mold or form around which the shoe is constructed. Based on dozens of measurements it determines everything about the shoe: length, width, volume, shape and height. Experienced shoe fitters know the last shapes of each shoe in their inventory and choose best fit based on foot size and anatomy.

Before industrial production methods evolved many shoes were made on straight lasts: there was no difference left to right. Of course, shoes could be hand made to fit each foot by skilled cordwainers. In 1880, Edwin Simpson created the first standard set of lasts in full and half sizes, using the 1/3 inch step-up for each full size, and 1/6th inch for each half-size. Interestingly, width measurement is determined by the circumference of the last at the ball, not by the width of the shoe. Each change in width, say D to E, equals a 1/4” more in the girth or volumetric measurement. As the shoe size increases all key dimensions of the last change proportionately in length, width, and girth.

It took a while for manufacturers to adopt Simpson’s system as it required them to invest in dozens of lasts for each style, and stores had to carry a lot more inventory for widths (A – EE+). Today, producing a full set of plastic lasts in multiple widths easily costs a quarter of a million dollars. Manufacturers get around this by making fewer widths (narrow, standard and wide) and sometimes only 1 width. Luckily, modern sneakers with stretchable or fabric uppers are more accommodating than traditional leather footwear. Shoes with molded synthetic soles may have only a single sole width per size. Although the upper comes in multiple widths they are attached to the same sole unit, and the wider upper bulges a little on each side.

Running and therapeutic shoe companies invest massive amounts of research, time and money into the development of their footwear. Each last is a core component of the protected design that ensures the unique fit of the shoe. For example, running shoes can be made over straight, semi-curved and curved lasts to cater for pronating, normal or supinating foot types. Some dress shoes are made with combination lasts that provide a narrower heel or back part.

Design and Fit

The design of a shoe informs the fit. Factors such as heel height, closure, topline (or height), upper material and construction determine the fit, look and cost of the shoe. For companies focused on “fast fashion” the priority is to keep up with or ahead of changing trends. Making shoes inexpensively and getting new styles out every 3-6 months is more important, fit and quality may be of minor concern. At the other end of the spectrum some consumers insist on well-made, long lasting comfortable shoes and are willing to pay extra for them. As traditional leather shoes and boots can also be re-soled or re-heeled to extend their useful life they can reduce the environmental burden on the earth.

Dress, athletic and therapeutic shoes each have different functions that inform the design and size choices. For example, many distance runners wear sneakers at least a half size up to protect their toes from blisters and bruising. On the other hand, soccer players prefer tight fitting boots to give them better contact with the ball and minimize internal foot movement. Therapeutic shoes pulled over extra-depth lasts come in multiple widths to accommodate wider feet, orthotic inserts and those patients with edema. Velcro closures make a shoe easier to don, and are quickly adjustable. Shoes with expandable uppers easily accommodate sensitive bunions and irritated hammertoes.

Conclusion

Given the variety of foot measuring systems, unique lasts, shoe designs and construction techniques it may not be possible to know one’s exact shoe size. Certainly, the basic measure of foot length alone is a poor indicator of fit. The real answer can be a moving target depending on the specific activity for which the footwear is intended. Ironically, although we take linear measurements of the foot, we are assessing fit for a shoe last which is essentially a series of curves. Always measure both feet, and fit the shoe to the longest foot. In the process, it is important to try shoes on as comfort is key. Unlike Cinderalla’s sisters, never fit the foot to the shoe. Although somewhat intangible a person quickly knows if the shoe “feels right” or it is “just a little off”.

Séamus Kennedy, BEng (Mech), CPed, FAAOP(A) is president and co-owner of Hersco Ortho Labs, New York. He can be contacted via e-mail at seamus@hersco.com or by visiting www.hersco.com.

Erick Janisse, CO, CPed, is sales training manager for Dr. Comfort footwear. With nearly 30 years of pedorthic experience, he is a well-known speaker and pedorthic educator.

References

Rossi, William A., Tennant, Ross. 1984. Professional Shoe Fitting. National Shoe Retailers Association